Business owner

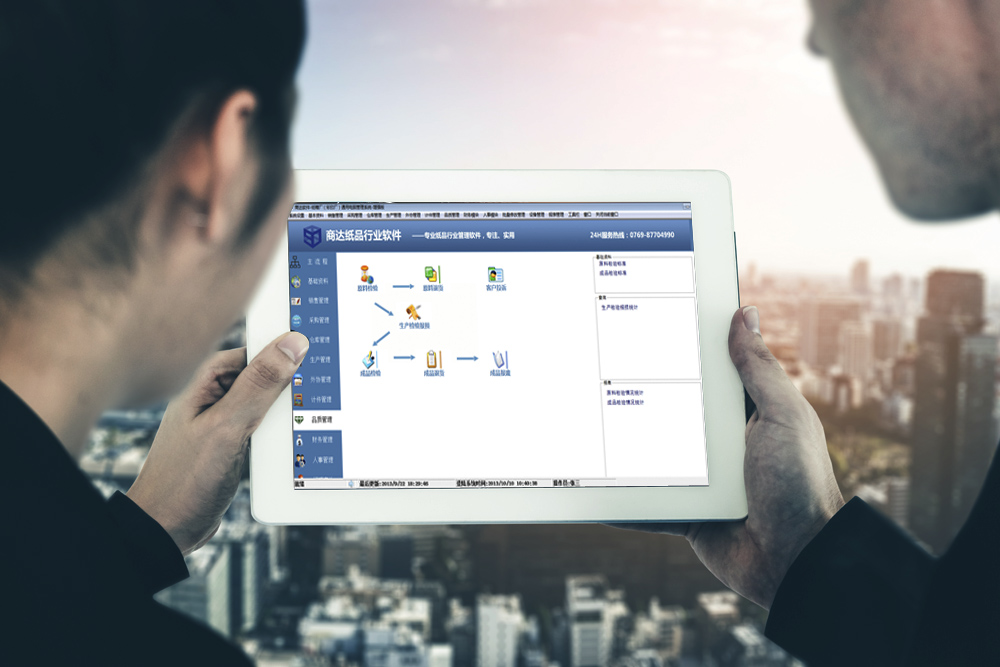

Real-time control, accurate analysis, and correct decisions are easier

The boss's confusion

Unable to timely and accurately understand the operating status of the factory, there is a time difference between data statistics and the real situation

The efficiency of manual statistics data is low, and the error rate is high, which is easy to cause adverse effects on decision-making

The enterprise management process is not standardized, and everyone shirks responsibility when there is a problem, and the responsibilities are not clear

Application value

The boss report helps the boss to understand the business situation in a multi-dimensional and all-round way

Rich analysis reports to help the boss timely and accurately understand the cost, profit, capital changes, receivables and payables information

Software management authorization model, standardize business processes, and clarify the responsibilities and permissions of employees

Financial supervisor

Simpler statement preparation and current accounts

Financial staff confusion

Manual transfer of business documents is prone to error, often uneven book, re-check time-consuming and laborious

The current account relationship is complex, it is very troublesome to deal with, and it is easy to make mistakes

Monthly salary accounting overtime, manual statistics efficiency is low, but also easy to cause dissatisfaction among employees

The boss often asks for a variety of statements, and the preparation of data often leaves the financial staff scrambling

Application value

The financial business is integrated, and the business documents are automatically generated to ensure that the financial accounts are consistent with the business, and to ensure that the financial accounts are accurate and fast

Automatically generate current statements to make reconciliation easier

Time piece wage classification accounting, fast income tax calculation, wage statistics and payment more efficient

Built-in rich report and flexible custom report function to reduce the workload of report preparation

Warehouse supervisor

Real-time inventory, early warning management, access management is simpler

The confusion of warehouse management personnel

Large turnover of personnel, new employees can not quickly and accurately find the material, often the wrong material situation

There is often a gap between the number of inventory and the number of books, and the material loss is serious but impossible to check

There are many batches of raw materials in storage, and some materials cannot be used beyond the shelf life due to reasonable arrangement, and the loss is great

Inventory records are not clear, and accurate data cannot be provided to reflect inventory status in time

Application value

Warehouse area division, easy to achieve accurate positioning of commodity materials, easy to find the storage location of raw materials

The document audit mechanism ensures the accuracy of various inbound and outbound data and helps enterprises to clearly understand the receipt and delivery of each material

Batch management and storage age management will effectively improve the utilization rate of raw materials, reduce inventory losses, and activate working capital

Real-time inventory and available inventory quick query, timely grasp the inventory situation, reasonable arrangement of production, purchase, sales plan

Purchasing supervisor

Easier price control, vendor management, and order tracking

The purchasing manager's confusion

The price of raw materials fluctuates greatly, there are many suppliers, the price control is relatively weak, and the inquiry is difficult

There are too many purchase orders, which are often lost, and the tracking of order execution is not in place

Poor communication with other departments, often missing or overbooking, booking wrong situation

Application value

Efficient purchase price comparison management, easy to understand the purchase history price and fluctuations, effectively reduce the purchase cost

The whole process of tracking the execution of orders, order early warning reminder and timely processing of procurement business, work efficiency is greatly improved

The Purchase Suggestion function automatically generates purchase orders to ensure that the order is produced with the lowest inventory

Sales executive

Performance statistics, price management and credit control are simpler

Sales manager confusion

There are many sales prices, and it is difficult to accurately grasp the price, which affects the sales quotation

The risk of sales return is high, and bad debts often occur, which brings great economic losses to enterprises

The execution of the sales order is unclear, and the shipment quantity is inconsistent with the order quantity

Sales performance can not be counted, and it is impossible to accurately grasp the good or bad sales of each product

Application value

Multi-level price management, easy to set sales prices according to customer level, product category, promotion time

Set customer credit rating reasonably, guide sales, and reduce payment risk

Detailed reports help sales staff understand the implementation of customer orders in procurement, production, delivery and settlement

Sales performance statistics and commodity gross profit analysis help management to better develop sales strategies

Production supervisor

It is easier to produce according to order, limit the quantity of materials and control the cost

The production manager's confusion

The procurement progress can not keep up with the production progress, and the situation of stoppage and waiting for materials often occurs

It is difficult to calculate daily output, unable to track production progress in time and adjust unreasonable production processes to ensure delivery time

The waste of raw materials is serious, but it is impossible to carry out effective statistics and trace the problem links

The product process is many, the material is complicated, the production cost statistics is time-consuming and laborious and easy to make mistakes

Application value

Set production by sales, purchase by production, and link the whole production process smoothly

The multi-dimensional report reflects the production progress in all aspects, and timely adjusts the unreasonable production process to ensure timely delivery

Obtain materials according to the production task sheet, strictly control material issuance, effectively trace the waste of raw materials, and reduce costs

The system automatically summarizes the costs generated in each stage of production, quickly accounting the production cost, and the data is more accurate

Confusion of merchandiser

Manual billing is time-consuming and laborious, with a lot of repetitive work

Manual calculation of the unit price, the use of materials is prone to errors, resulting in inconsistent accounting with the customer, the procurement of wrong materials, while manual single purchase is easy to miss the single purchase, resulting in production and other materials, unable to deliver according to the customer's delivery time

The merchandiser has to deal with a lot of work every day (answering the phone, making phone calls, tracing cardboard, tracing printing plates, scheduling production, marking, counting cardboard, writing production orders, placing purchase orders, writing delivery orders, writing labels, arranging delivery), and has a large workload.

Customers ask the status of the order, always go to the workshop to check, time-consuming and laborious

Application value

System billing saves time and easily processes orders

The system automatically calculates the unit price and materials according to the custom formula, which is accurate and fast

The system is a good helper of the document, automatic calculation, order, intelligent reminder, saving time and reducing labor costs

System order tracking, real-time order status at any time, quickly and accurately answer customer orders

Quality control manager

Management is orderly, clear and orderly

The quality control manager's confusion

A large number of product quality standards, find trouble, registration records prone to error

The quality inspection records are trivial, the handwriting efficiency is low, the statistics are troublesome, and the shipment is often delayed because of the shipment quality inspection reports and product labels

Product quality tracking can not be timely reflected

Application value

Technical department product set production data is complete, product quality standards are customized, record fast, convenient and quick access

Instant entry of quality inspection records, automatic printing of quality inspection reports, product labels, fast shipment

Timely reflect and track product quality, convenient to investigate the source of problems, improve product quality

If you want to further understand Shangda's products or solutions

You can fill out the form below, and we will contact you as soon as possible and recommend products that meet your needs, providing you with solutions.

Copyright © 2023 Dongguan Shangda Software Development Co., Ltd. Yue ICP Bei 13055119

Service hotline:0769-88800840